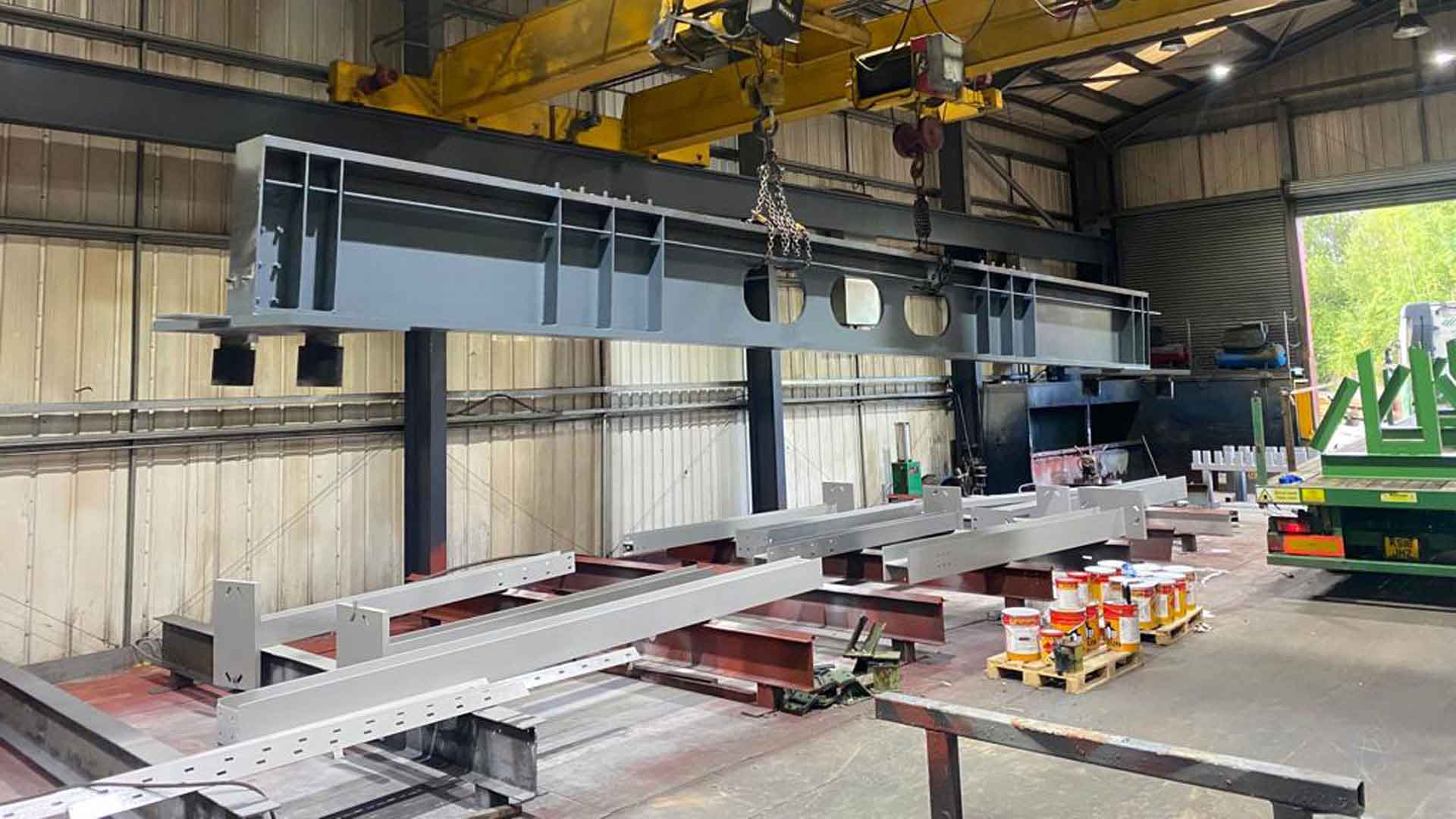

Plate Girders

Fully fabricated and shorter lead time than industry standand

![]()

Midland Structures can produce plate girders, box girders, bridge beams and cellular beams up to a single weight of 20t. Assembly and welding is carried out on a Corimpex column and boom submerged arc welding line, which is also equipped with a hydraulic assembly jig.

Midland Structures have the capacity to produce large volume carcass beams or complete fabricated members. In addition to this, we are able to offer protective coating including intumescent paints.

Midland Structures are often able to offer shorter lead times than many other manufacturers.